How is a latex mattress made?

No worries Bella! We milk the rubber tree, not you.

The raw material that goes into our latex foam mattress is natural latex milk harvested from rubber trees (Hevea Brasiliensis). These trees grow on rubber tree plantations in the Southern part of Thailand.

The rubber farmer will manually cut a wedge in the bark of the tree and “tap” the milk. The latex milk will flow into a small container attached to the tree. If done correctly, this process does not harm the tree in any way.

The collected milk is then sent to the processing plant.

So how does the ‘tree sap’ become a foam mattress? In order to mould the latex milk into a mattress shape, it must undergo the process of vulcanisation. This is a process in which the raw latex milk is mixed with additives and heated.

Compare it to baking a cake. You can’t make a cake just by pouring milk into a cake pan and shoving it in an oven. You will need to mix in other dry ingredients (i.e. flour, baking soda,…) so your batter will actually turn into a yummy cake when you bake it.

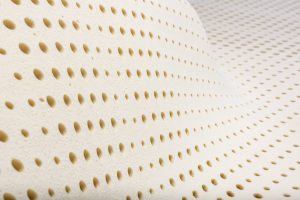

So we add some ingredients to the raw latex milk (i.e. foaming agents) before we pour it into the mattress mould. Next, the mould is heated and the mixture turns into foam. The natural latex foam is carefully removed from the mould and washed with soap and water. It is then dried and inspected for imperfections.

No cake is finished without some icing. We top off our mattress cake with a (GOTS) certified organic cotton cover. Now all you have to do is put the cherry on top!